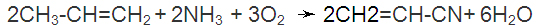

In the SOHIO process, propylene, ammonia and air (oxidizer) are passed through a fluidized bed reactor containing the catalyst, based on bismuth phosphomolybdate between 400-510 °C and 50-200 kPag.

The reagents pass through the reactor only once, before being cooled in aqueous sulfuric acid. Excess propylene, carbon monoxide, carbon dioxide and nitrogen that do not dissolve are either vented directly into the atmosphere or incinerated.

The aqueous solution consists of acrylonitrile, acetonitrile, hydrocyanic acid and ammonium sulfate produced from excess ammonia.

A recovery column removes water and acrylonitrile and acetonitrile are distilled off.

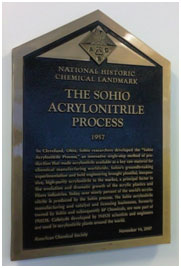

Historical plaque conferred by ACS to INEOS

Historical plaque conferred by ACS to INEOS

by the chemical landmark of the SOHIO

process for the production of acrylonitrile

HISTORY OF THE DISCOVERY OF THE SOHIO ACRYLONITRILE PRODUCTION PROCESS

You may not know it by name, but acrylonitrile affects almost everyone in some way, every day. Acrylonitrile is the key component in acrylic fibers used in clothes, in the plastics used in the manufacture of TV parts and electro-electronic equipment, in automobiles, in carbon fiber and in sports equipment. The material used in these and many other products was produced by a process discovered and developed in the 1950s by scientists and engineers of the Standard Oil of Ohio (SOHIO), which later became part of the oil company BP. BP's nitrile business was sold to INEOS in 2005.

Brief history of acrylonitrile

The discovery and commercialization of the SOHIO acrylonitrile process was the result of talent, imagination, teamwork and the risk-taking attitude by the SOHIO employees. The SOHIO’s discovery led to the production of cheap, high-purity acrylonitrile as a raw material, which led to a dramatic growth in the thermoplastic, synthetic fibers and food packaging industries.

The acrylonitrile that was first synthesized in 1893 by Charles Moureu did not become important until the 1930s, when the industry started using it in new applications, such as acrylic fibers for textiles and synthetic rubber. Although in the late 1940s the utility of acrylonitrile was not questioned, existing manufacturing methods were expensive and the processes took several steps. They seemed reserved for the largest and richest manufacturers in the world: American Cyanamid, Union Carbide, DuPont and Monsanto. With such high production costs, acrylonitrile could very well have remained little more than an interesting, low-volume special chemical with limited applications.

In the late 1950s, however, SOHIO's research on selective catalytic oxidation led to an innovation in the manufacture of acrylonitrile. The people who invented, developed, and marketed the process showed as much skill in marketing as in chemistry. The result was such a dramatic reduction in process costs that all other methods of producing acrylonitrile, predominantly using acetylene, soon became obsolete.

Discovery of the SOHIO Process

Founded by John D. Rockefeller, SOHIO was an oil company known for efficient refining and qualified marketing. Before 1953, he had not researched chemicals or petrochemicals; the research was limited to the development of petroleum products and processes. Nobody among the 80 researchers working in the SOHIO laboratory, located on Cornell Road in Cleveland, was thinking of a shortcut to the production of world-class acrylonitrile.

The picture changed when Franklin Veatch, research supervisor, reported to E.C. Hughes, director of SOHIO research, proposing that the conversion of light refinery gases, such as aliphatic hydrocarbon propane, into oxygenated oxygen-containing compoundscould be profitable. At the time, oxidation of aliphatic hydrocarbons was primitive and expensive. Veatch's idea was to use metal oxides to convert hydrocarbons to oxygenates. The funding was approved for this effort in 1953.

In addition to starting new research, SOHIO ventured into the petrochemical business by building ammonia and nitrogen plants in Lima, Ohio, and near Joplin, Missouri, to use by-products from its oil refinery. It was a conservative move, but it encouraged SOHIO to view chemicals as a commercial company; an undertaking that would lead to notable success.

The first experiments in Veatch's research did not produce major developments, and he was given a six-week deadline. The resulting program was successful when a test run was performed with propylene over a modified vanadium pentoxide oxidant and the resulting odor was instantly recognized as acrolein. Veatch knew that yet another oxidation step would lead acrolein to acrylic acid - an important, expensive, and fast-growing monomer.

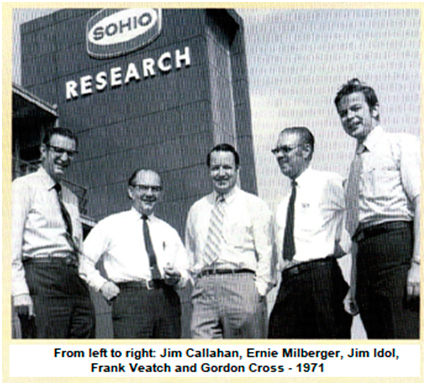

Over the next two years, several researchers, including Ernest C. Milberger, James L. Callahan, Robert W. Foreman, James D. Idol Jr., Evelyn Jonak and Emily A. Ross, were involved in this development effort.

In 1955, the team started testing oxidants as catalysts for direct oxidation. In an experiment developed by Jim Callahan and conducted by Emily Ross, bismuth phosphomolybdate produced acrolein in yields of 40% or more. This was a discovery of first magnitude: propylene to acrolein in a single catalytic reaction step. Acrylic acid can be produced in a subsequent step. Callahan, Foreman and Veatch secured the major patents for the bismuth phosphomolybdate catalyst and, from then on, things were bound to happen quickly.

Jim Idol suggested acrylonitrile as a derivative of acrylic acid and successfully performed the catalytic conversion of the ammonium salt from acrylic acid. Then, acrylonitrile was produced by feeding acrolein, ammonia and air over the catalyst that produced acrylic acid from acrolein. This success suggested that acrylonitrile could be produced directly from propylene, carrying out the entire reaction in one step with bismuth phosphomolybdate. The experiment, designed by Idol and carried out by Evelyn Jonak in March 1957, resulted in ammoxidation, a process that produced acrylonitrile with about 50% yield together with acetonitrile and hydrogen cyanide as by-products.

With the ability to produce acrolein, acrylic acid and acrylonitrile by new, efficient, and revolutionary processes, Veatch pushed for a strong development and commercialization effort. The Patent and Licensing department started working to secure a special patent position. As the manufacture of acrylic acid and acrylonitrile has proved to be very promising, the production of acrylonitrile had become the priority.

SOHIO invests in the production of acrylonitrile

SOHIO's process savings for acrylonitrile were so positive that the decision was made to proceed with commercialization, although initial market development efforts were discouraging. The main users were not sure that SOHIO acrylonitrile would satisfy their needs. A large chemical company declined the opportunity for a joint venture. Another company announced plans for a new 100-million-pound acrylonitrile plant based on old acetylene technology at a cost of US$ 100 million.

Still, SOHIO commissioned the project for a detailed acrylonitrile plant. A pilot plant was built under the direction of Gordon G. Cross in the new SOHIO laboratory in Warrensville Heights, in thesuburb of Cleveland, where Ernie Milberger was fundamental in designing large scale laboratory reactors, obtaining project data and working on processdevelopment.

In a bold move, it was decided to design the commercial plant based on bench-scale laboratory development data, instead of waiting for the results of the pilot plant. The time gained from eliminating this stage of development outweighed the added risk. The Milberger bench scale unit, which required about 1.5 kg of catalyst, generated the main data for the design of commercial reactors with a capacity of 40 tons.

In early 1958, commercial design was advancing under the direction of Edward F. Morrill; a pilot plant was in operation; the catalyst was in final development by Callahan and his team, with provisions for large-scale manufacturing; and the work on advancing the reactor’s operation, product purification and waste disposal was being coordinated. A key innovation was the successful development of a fluidized bed catalyst to allow removal of the heat produced by the ammoxidation reaction.

By the middle of the winter of 1959-60, the Lima plant, in Ohio, which cost $ 10 million to build, was completed. In less than four years since the discovery of bismuth phosphomolybdate as a catalyst for direct oxidation of propylene and the discovery of propylene oxidation, a large-scale commercial plant designed to produce 47.5 million pounds of acrylonitrile per year was ready to operate.

Only one challenge remained - an economic one. Soon after SOHIO's entry, a major manufacturer cut its price in half. SOHIO reached the lowest price and still managed to profit. The competitor discarded its own expansion plans and took out a SOHIO license. Other acrylonitrile producers soon became licensed in the SOHIO process and, in a few years, the production of acetylene-based acrylonitrile was replaced by the SOHIO process.

In order to gain a larger share of the general market, SOHIO decided to promote the licensing of the process, instead of maintaining manufacturing alone. The SOHIO license for the Republic of China in 1973 was the first transaction by an American company after China opened its doors to investments in the USA. Today, the SOHIO Acrylonitrile Process is used in more than 90% of the world's production of acrylonitrile, representing plants in sixteen countries worldwide. The annual production of acrylonitrile increased from 117,000 tons in 1960 to more than 7 million tons in 2020.

Since 1960, several improved catalyst formulations have been developed, most of which are based on the original bismuth phosphomolybdate catalyst. INEOS' current research focuses on further improvements in the SOHIO's acrylonitrile process.

The people behind the SOHIO process

Six people played the most important roles in the SOHIO's acrylonitrile project.

Franklin Veatch was a research supervisor of petrochemicals, polymers, and new petroleum processes. He had a technical and creative mind and inspired his co-workers to achieve a goal, however impossible it seemed. Veatch received his bachelor's and master's degrees from the University of Arizona and his doctorate. from Stanford University in 1947. He held 61 US patents when he retired in 1978. He passed away in 1980.

James L. Callahan, a research associate, coordinated the research and development of catalysts, including the discovery of improved methods of making catalysts. He was known for converting hydrocarbon materials into petrochemicals. Callahan received his bachelor's degree and master's degree from Baldwin-Wallace Collegeand, in 1957, his doctorate from Case Western Reserve University. Retired since 1985, he receives more than 200 patents and publications.

Edward F. Morrill, as president of Vistron Corp., he was the champion of the product process on the commercial side. Vistron was SOHIO's chemical division from 1966 to 1982. Morrill received his bachelor's degree in civil engineering from the Case Institute of Technology in 1929. His ability to "see" a revolutionary and economically dominant chemical process was crucial to the project's success. Morrill took the necessary risks that led to successful commercialization.

James D. Idol, Jr., an associate researcher who supervised and conducted research and feasibility tests, who holds the basic patent for the process. He received his bachelor's degree in chemistry from William Jewell College and, in 1955, his Ph.D. in chemistry from Purdue University.

Ernest C. Milberger, associate researcher, conducted the improvement of the SOHIO process, from small-scale research to the pilot plant. He received his AB and MA degrees in chemistry from the University of Missouri and his Ph.D. from Case Western Reserve University in 1957. He holds 80 patents, mainly in the field of catalytic processes.

Gordon G. Cross, development supervisor, was responsible for developing the pilot plant for the SOHIO process, as well as for preliminary engineering and pre-commercial economic evaluation of the overall process concept. He received his bachelor's degree in chemical engineering from Ohio State University and, in 1960, his master's degree in engineering administration from the Case Institute of Technology.

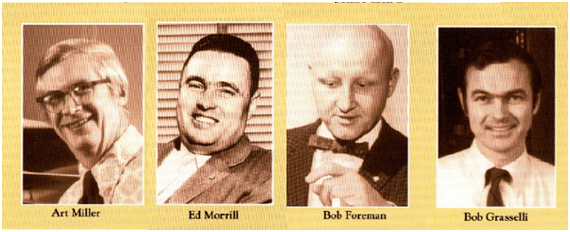

Other significant contributors to the invention, development and commercialization of the SOHIO process include

Arthur F. Miller, an associate researcher who developed the commercial method for the manufacture of improved catalysts;

Robert K. Grasselli, a catalyst research associate who was involved in the initial oxidation research, in the development of subsequent generations of SOHIO catalysts and in the detailed mechanisms of ammoxidation reactions; and

Robert W. Foreman, group leader during the initial phase of the research and co-inventor of the propylene-acrolein phosphomolybdate bismuth catalyst.

Summary of the original document:

A National Historic Chemical Landmark - SOHIO Acrylonitrile Process

American Chemical Society (ACS) 1996

https://www.acs.org/content/acs/en/education/whatischemistry/landmarks/acrylonitrile.html