THERMPAN AND ITS PROPERTIES

Home > THERMPAN and its properties

The physical and mechanical properties of THERMPAN may vary due to the type of copolymer

used in the preparation of the resin and its molecular weight. For this reason, different types

of THERMPAN resins can be produced according to a specific need.

THEMPAN fibers

For a PAN copolymer with 6% of polyvinyl acetate with Mw of 120,000 Daltons, the following

values are found:

Without stretching

Composition |

PAN- co-polyvinyl acetate 6% |

Molecular Weight (Mw) |

120.000 |

Extrusion temperature |

220°C |

Tenacity (MPa) |

45 |

Module (GPa) |

2,9 |

Specific deformation (%) |

5,0 |

With 14X stretching

Composition |

PAN- co- Acetato de Polivinila 6% |

Molecular Weight (Mw) |

120.000 |

Extrusion temperature |

220°C |

Drawing temperature |

180ºC |

Tenacity (MPa) |

625 |

Module (GPa) |

10,1 |

Specific deformation (%) |

5 a 8 |

For 25 dtex multifilament fibers produced with the same polymer and stretching rate of 8X,

the tenacity is 23 cN/tex and the elongation is 11%.

Surface Energy

The surface energy of THERMPAN resin films evaluated in terms of its contact angle (θ) is

approximately 65º, reaching 28º with treatment of its surface with nitrogen plasma, which

means that it presents better adhesion than PP (90°), PET (92°) and PVC (86 °), for example, to

cement or common adhesives on the market.

Thermal Stabilization

THERMPAN fibers can be easily de-plasticized by washing with hot water and, after this

process, they have the same thermal stabilization characteristics as the PAN fibers obtained by

wet spinning.

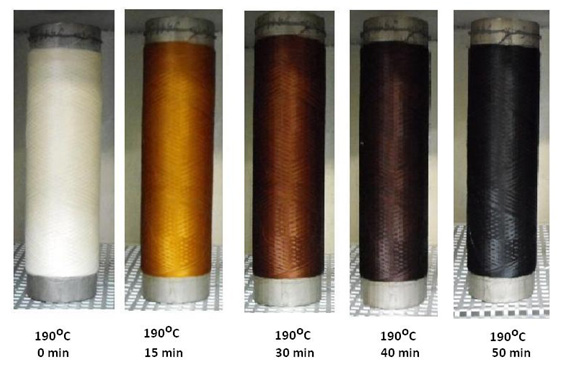

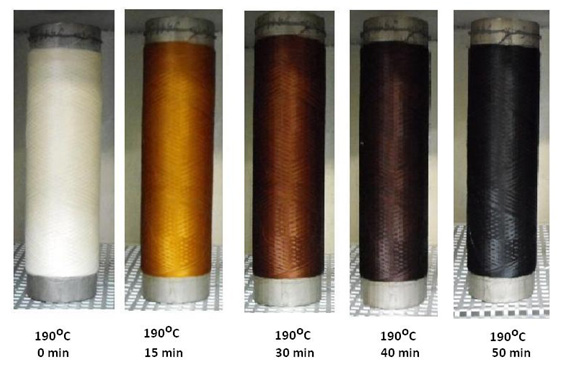

Thermal stabilization of Thermpan fibers at 190ºC

Thermal stabilization of Thermpan fibers at 190ºC

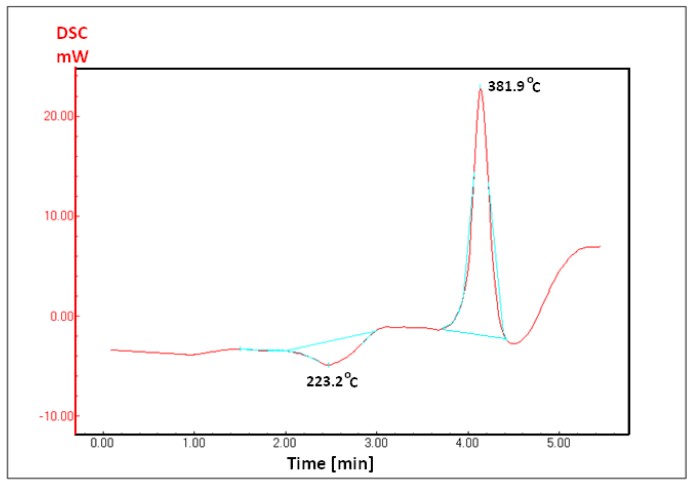

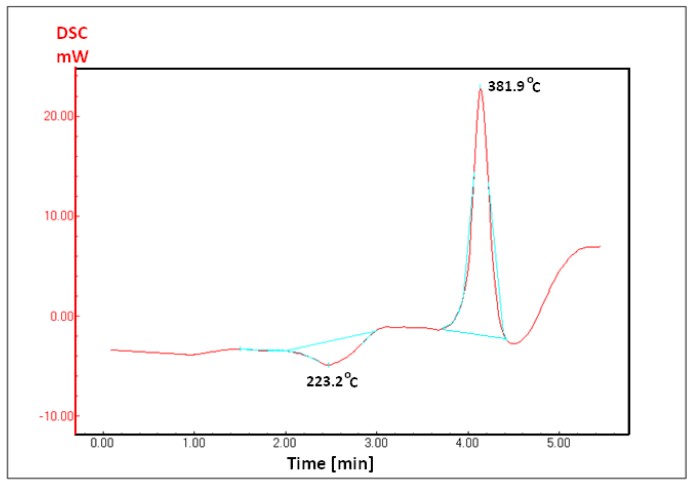

Thermal analysis

Thermal analysis (DSC) shows the melting peak of THERMPAN, approximately 150ºC below the

exothermic cyclization peak of PAN present in the resin.

Typical DSC analysis of a THERMPAN resin

Typical DSC analysis of a THERMPAN resin

Peaks: 223.2ºC Melting; 381.9ºC Cyclization

Rheological Analysis

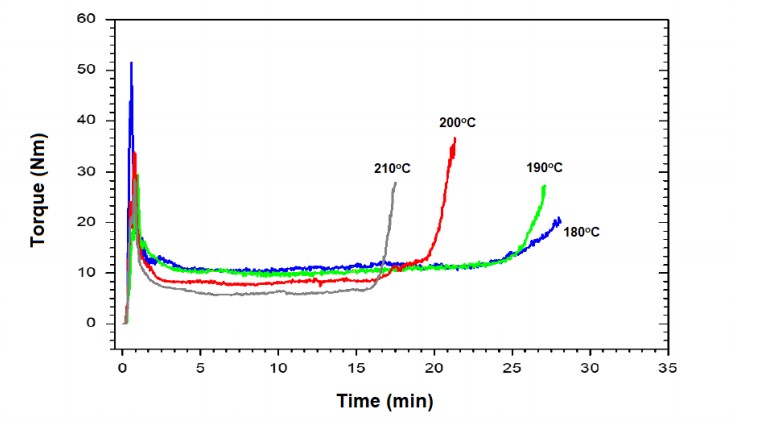

The rheological analysis shows that the lower the working temperature of the THERMPAN resin in the extruder, the longer the residence time within the viscosity range that allows its flow and desired conformation is. With a THERMPAN resin that shows good fluidity at 180ºC, its residence time before the viscosity increases due to cyclization and cross-linking is 25 minutes. For temperatures around 240ºC, this time is reduced to approximately 3 minutes.

Typical DSC analysis of a THERMPAN resin

Typical DSC analysis of a THERMPAN resin