TECHNOLOGIES EMPLOYED IN THE MANUFACTURE OF ACRYLIC FIBERS

Home > Technologies Used in the Manufacture of Acrylic Fibers

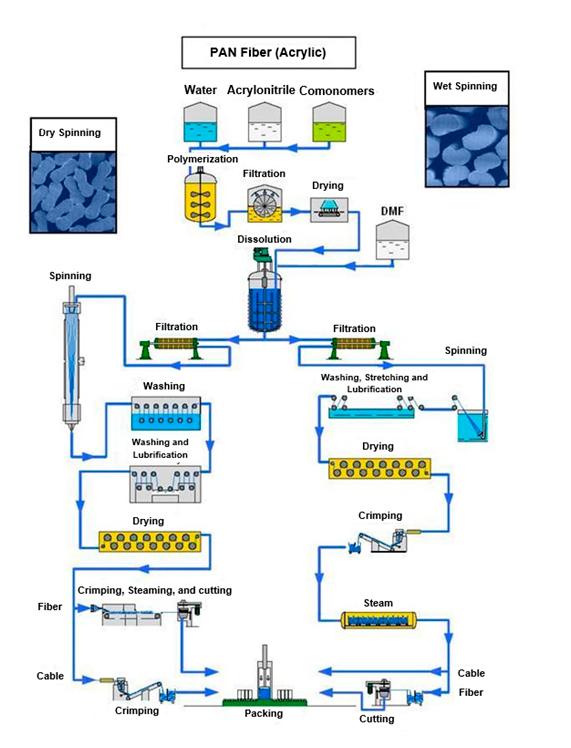

Given the non-thermoplastic characteristics of PAN, only two fiber production processes are supplied and both require solvents for dissolution of the polymer prior to spinning. The first process to be invented, known as

wet spinning was patented by Du Pont (USA) in 1946 and the fibers produced by it were registered with the name "Orlon". Shortly after, the Bayer company of Germany patented the process known as

dry spinning and began to produce its fibers with the brand "Dralon". The main difference between these two technologies is in the spinning process: whereas in the wet spinning the PAN dissolved in the solvent forms the fibers by a coagulation process in an aqueous bath, in the dry spinning the solvent is evaporated in a tower heated with hot air which forms the filaments. The remaining of the process is similar in both and the fibers have practically the same properties and applications. In wet spinning, the solvents of the polymer may be organic solvents or salts, the most common being dimethylformamide (DMF), dimethylacetamide (DMAc), dimethylsulfoxide (DMSO) and sodium thiocyanate solution (NaCNS).

Some companies that produce carbon fiber use the zinc chloride solution (ZnCl

2). It has now been suggested to use ethylene carbonate and propylene carbonate because they are low toxicity solvents however more expensive. In the past some companies have used nitric acid as solvent for PAN in wet spinning, but it has been abandoned.

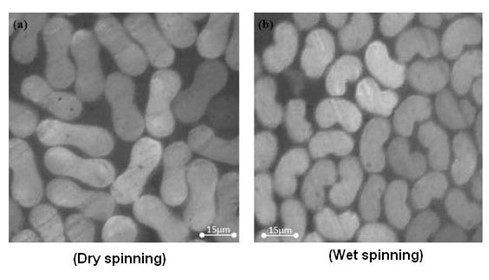

In dry spinning technology, only organic solvents are used and it is not possible to use salts. Only two solvents are used in this process: dimethylformide (DMF) and dimethylacetamide (DMac), with the advantage that this second is safer because of its higher flash point. Another common point in both technologies is that all of the solvent used needs to be recovered for cost and environmental reasons, being made in an existing distillation unit in the plant itself, which represents the highest energy consumption in the spinning process. The most widely used technology in the production of acrylic fibers is wet spinning. The differentiation of the fibers produced by wet and dry spinning processes can be easily performed by microscopy. The cross-sectional profile of the fibers obtained by dry spinning is a "bone" and while those produced by wet spinning resemble a "bean".